When lubrication is required as well as cooling, lubricating mist can be reduced and cooling enhanced.

Heavy coolant can be messy, costly and must be carefully maintained. Dry machining is not always possible due to the need for lubrication or additional cooling that cold air alone cannot provide.

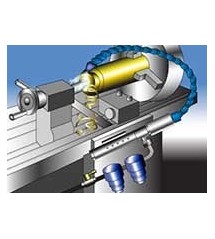

The unique patent pending low cost Frigid-X™ Sub-Zero Vortex™ Tool Cooling Mist System is ideal for these applications. The unit is comprised of a coolant/lubrication suction system which draws any water based liquid into a specially designed delivery system. This cools the liquid to deliver a very cold fluid “mist” at around 40ºF (5ºC). This cooling allows for as much as 20% less coolant needed, faster production rates and improved quality. An Adjusting screw controls the amount of mist required. Simple operation, no moving parts except for the adjusting screw means long life, low cost operation and zero maintenance.

The result is a low cost and essentially maintenance free system that supplies cold liquid reducing the mist volume by as much as 20%, enhancing the environment and safety while reducing the cost of coolant or lubricant.

The liquid is cooled using a small vortex tube that uses 5 SCFM (142 SLPM) at 50 psig (3.5 bar). An adjusting screw controls the level of mist. Liquid is siphoned into the unit using a long plastic tube connected to the main unit. A heavy duty removable magnet secures the system. Magnet can be removed and mounting holes used to secure the mist system. Only moving part is the liquid flow adjusting screw to assure long life and maintenance free operation.

Advantages:

-

No electricity required - simplicity in design

-

low cost, no costly pump system

-

reduces coolant/lubricant cost using by less fluid

-

improves safety with less mist

-

no moving parts except for an adjusting screw for the fluid

-

small and lightweight, portable

-

maintenance free operation

-

-

Wherever lubrication is required in machining

-

When cooling is required beyond the capability of cold air alone

How It Works

The liquid is cooled by means of a small vortex tube that uses around 5 SCFM (142 SLPM) at a maximum of 50 psig (3.5 bar). Pressure can be adjusted up or down slightly to avoid freezing of the liquid or to get a colder temperature. An adjusting screw controls the level of mist required. Liquid is siphoned into the unit using a long plastic tube connected to the main unit. A heavy duty removable magnet secures the Frigid-X™ Sub-Zero Vortex™ Tool Cooling Mist System onto a machine. The magnet can also be removed and mounting holes may be used to secure the mist system. All you need is the liquid to cool and/or lubricate and a small amount of filtered (clean) compressed air at 50 psig (3.5 bar). No electrical components, no expensive pumps or moving parts except for the adjusting screw assures long life and maintenance free operation.

Dimensions

Operation

The liquid is cooled by means of a small vortex tube that uses around 5 SCFM (142 SLPM) at a maximum of 50 psig (3.5 bar). Pressure can be adjusted up or down slightly to avoid freezing of the liquid or to get a colder temperature.

An adjusting screw controls the level of mist required. Liquid is siphoned into the unit using a long plastic tube connected to the main unit. A heavy duty removable magnet secures the Frigid-X™ Sub-Zero Vortex™ Tool Cooling Mist System onto a machine. The magnet can also be removed and mounting holes may be used to secure the mist system.

All you need is the liquid to cool and/or lubricate and a small amount of filtered (clean) compressed air at 50 psig (3.5 bar). No electrical components, no expensive pumps or moving parts except for the adjusting screw assures long life and maintenance free operation.