- Out-of-Stock

Ultrasonic Leak Detector

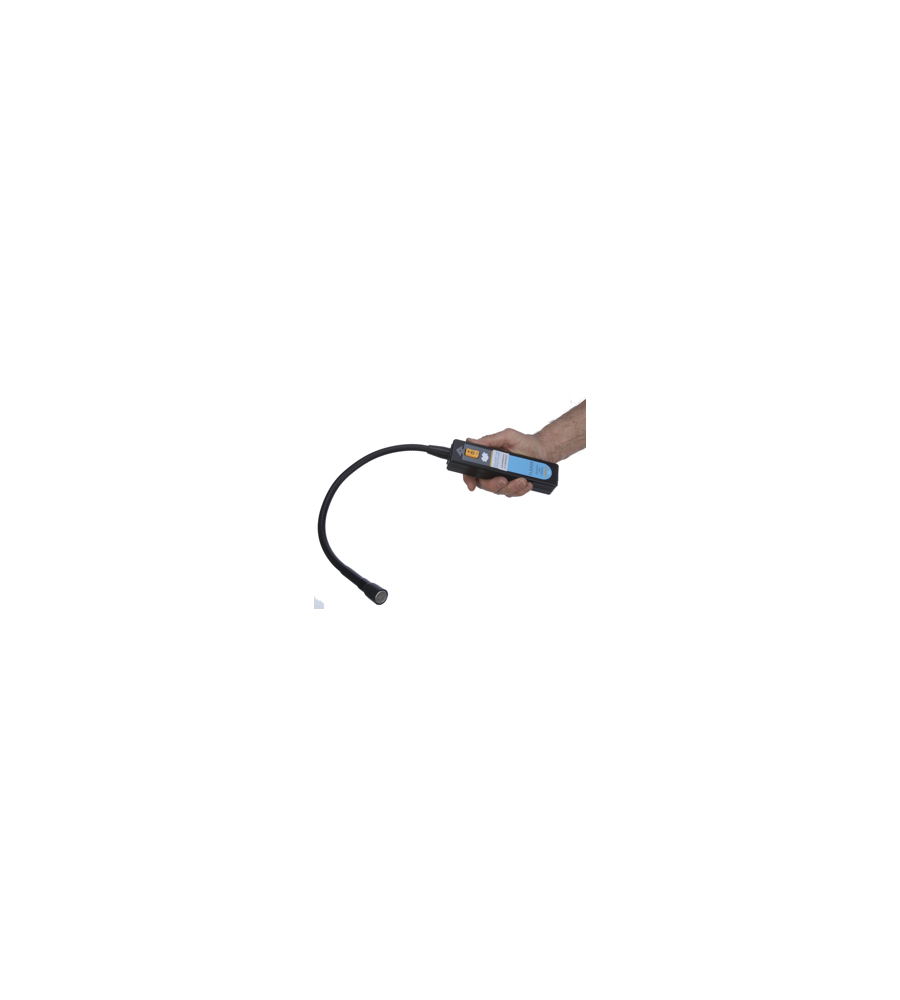

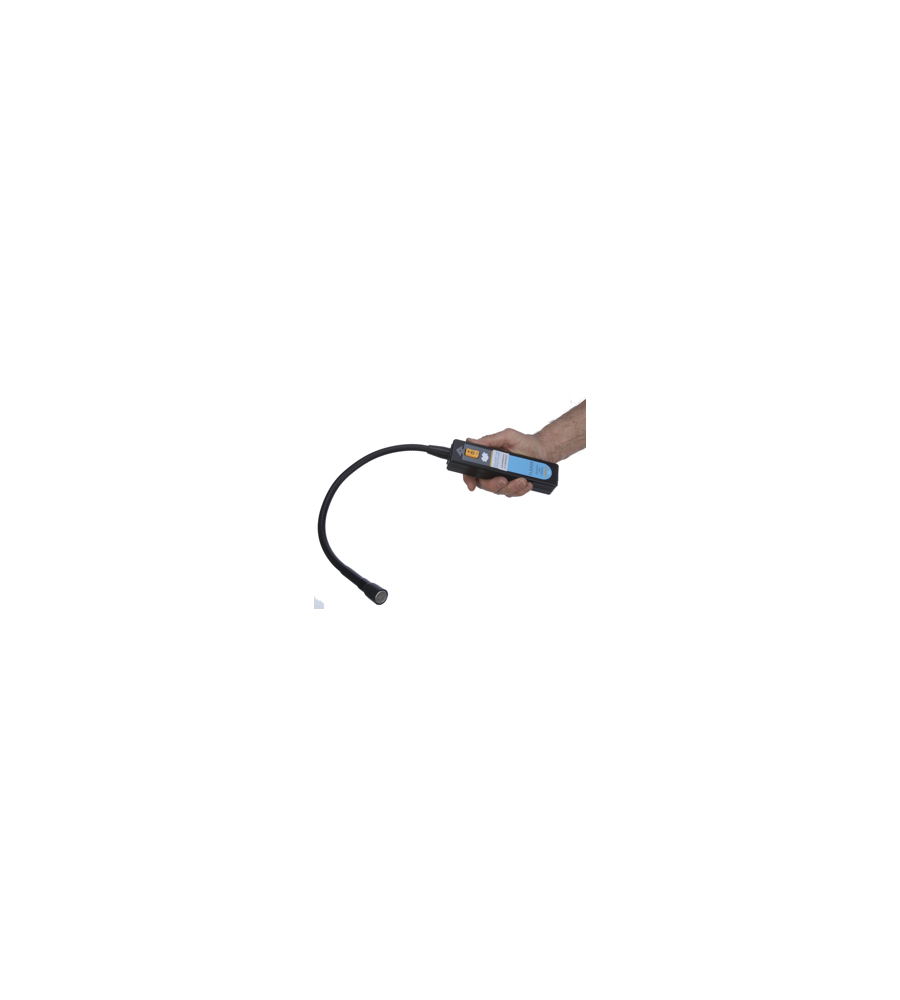

NEX FLOW™ "FLEX.US" Ultrasonic / Ultrasound Leak Detector

The FLEX.US ultrasonic leak detector kit comes with the FLEX.US unit and manual and utilizes two AA alkaline batteries (included).

The FLEX.US ultrasonic leak detector kit comes with the FLEX.US unit and manual and utilizes two AA alkaline batteries (included).

The FLEX.US is a complete kit - the high quality flexible sensor is mounted on the end of a flexible steel pipe so the ultrasonic sound can access hard to reach areas. The unit converts the ultrasonic noise of a leak into a sound humans can hear (hissing sound) and not just some beeping sound or LED display that may not distinguish a leak sound from other phenomenon.

The headset has excellent noise attenuation for use in the noisiest of environments.

A rugged carrying case protects your FLEX.US when not in use.

The FLEX.US is a solid tool - built to last, it is easy to use and will provide many years of service.

Why our Ultrasonic/ Ultrasound Leak Detector Does the Job and Why Others May Not

REMEMBER: The better the system, the more leaks you find and the more money you save!

Always beware of cheap ultrasonic leak detector that just may not do the job. Ours do the job because of the following:

FIRST: Look at the headphones. If they are an open walkman style, these will be useless in a noisy plant because they offer absolutely NO protection from the ambient noise which can be at high levels! (After all, why else would you need an ultrasonic lead detector!). So how can you hear the leak in the headphone without protection from the ambient audible noise in the plant? Our headphones completely cover the ear providing 130dB hearing protection. Some competitive units would not be useable in a typical factory where hearing protection is mandatory because the inspector would have to insert ear plugs in his ears. Our headphones don't require this.

SECOND: Look at frequency range. Our frequency is centered at 38.4 kHz with an open window of +/- 2kHz. By having a bandwidth this narrow we are able to eliminate other sources of ultrasonic parasite noise. It is absolutely critical that you amplify just this narrow single harmonic band of sound. Some detectors amplify EVERY frequency from 20kHz up to 100kHz. That's because the manufacturer did not include any low pass filters. This also affects the output signal in the headphones. It also affects the directionality of the device. At low frequency it is much more difficult to know where the sound is coming from because the wavelength is larger and more reflective.

THIRD: Extension tubes. For accessing tight areas some firms suggest using a hollow tube (tubular extension) with their system. Ultrasound will not travel well into this tube so the equipment will be less sensitive in hard to reach areas. If the tube is 6" long for example, that means the sensor is always a minimum of 6" away from the source. The Nex Flow™ system sensor is at the end of the flexible extension so the sensor is "always" directly exposed to the leak making our equipment much more sensitive. If more sensitive of course you will more easily detect the leak (one you may not even find it with another system.)

Nex Flow™ aims to be the lowest cost where possible but NOT at the expense of sacrificing quality.

The Ultrasonic Leak Detector supplied by Nex Flow™ may also be used as an ultrasonic vacuum leak detector.

Nex Flow’s Air Amplification Technology Goes Beyond Air leaks – recovering energy at point o use in blowoff applications.

Compressed Air Leaks are a huge source of energy loss. Our Ultrasonic leak Detector is designed to “easily” detect the source of these leaks. Once found “Sealing Air Leaks” can save enough air to often operate many Nex Flow™ products!